New with us: Aconity3D

Aconity3D is renowned as a provider of flexible, application-specific Additive Manufacturing (AM) systems for metals. Leveraging their technological expertise in production and informatics, the company aims to push the boundaries of state-of-the-art 3D printing for metal components. Their focus includes working with challenging materials such as magnesium alloys and enhancing productivity. As the first provider, Aconity3D now enables the production of magnesium components from WE43 on the PROTIQ Marketplace.

WE43 is a high-strength magnesium alloy with excellent corrosion resistance and favorable mechanical properties at both room temperature and elevated temperatures up to 300°C. Due to its low density and biodegradability, WE43 is suitable for both technical and medical applications. Combined with the advantages of the LBPF process in creating intricate parts, this material offers solutions for mechanical engineering and medical technology.

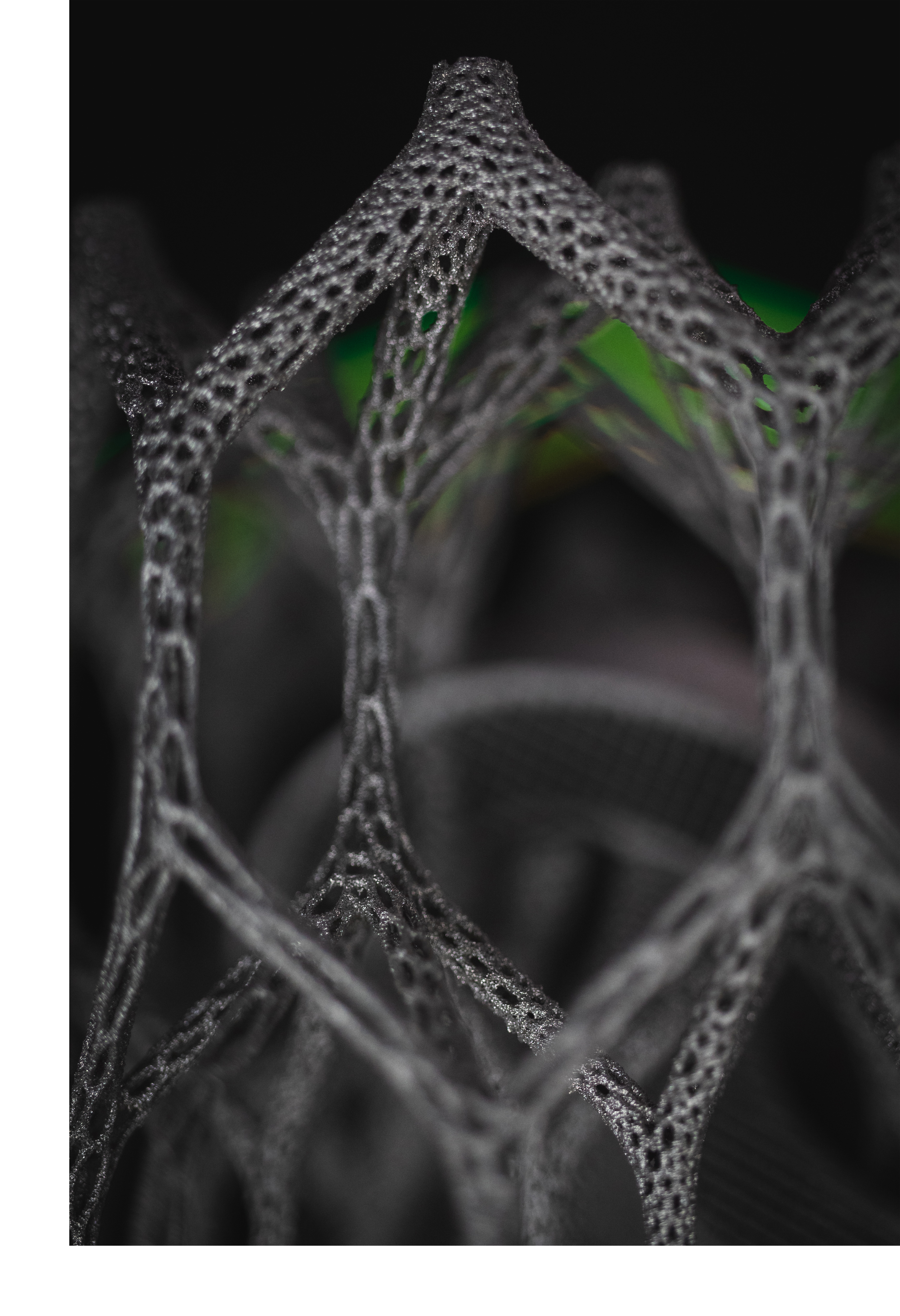

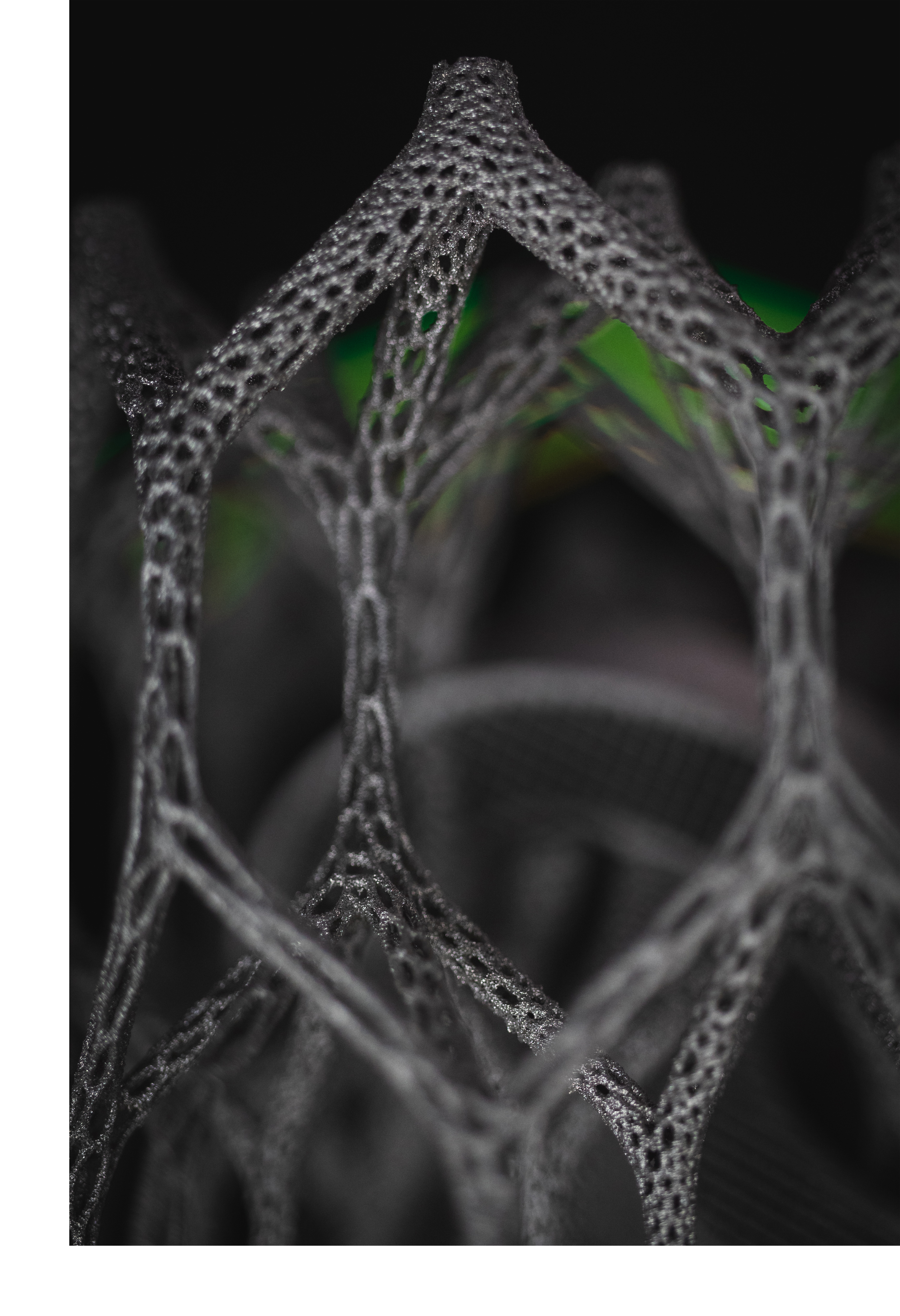

Exemplary applications of Aconity3D:

Exemplary applications of Aconity3D:

Hairpin windings, combustion chambers and induction coils made of pure copper, magnesium inserts for carbon fiber monocoques in racing and structural components made of aluminum and magnesium in the automotive industry.

Furthermore, injection molds made of 1.2343 are additively manufactured for the tool shop to reduce cycle time and increase service life.

Aconity3D also relies on additive manufacturing in its own plant construction and produces gas coolers for the shielding gas flow of AM systems and holders for the galvanometer scanners themselves, among other things.

More News

Are your 3D files ready?

Just upload your data. All files are automatically checked and optimized for printing.

Deutsch

Deutsch English

English Italiano

Italiano

.jpg)

Exemplary applications of Aconity3D:

Exemplary applications of Aconity3D: