Aluminum oxide reinforced zirconia (ATZ): Now new on the PROTIQ Marketplace

Technical ceramics are increasingly in demand as they offer outstanding material properties that make them an excellent alternative to metals or plastics in some applications. Aluminum oxide and zirconium dioxide are the most commonly used ceramics. CADdent continuously tests and develops manufacturing strategies for new materials in order to introduce them to the market at an early stage. One such innovative material is ATZ (Alumina Toughened Zirconia), which is now also available on the PROTIQ Marketplace. Find out more about the properties of ATZ and how it differs from conventional zirconia.

Advantages of technical ceramics

Technical ceramics offer a combination of exceptional strength, hardness and high resistance to extreme temperatures, corrosion and chemicals. These properties make them durable and high-performance alternatives to materials such as metals and plastics. Additive manufacturing also overcomes the technical production limitations of traditional processes.

Precision through LCM process

Precision through LCM process

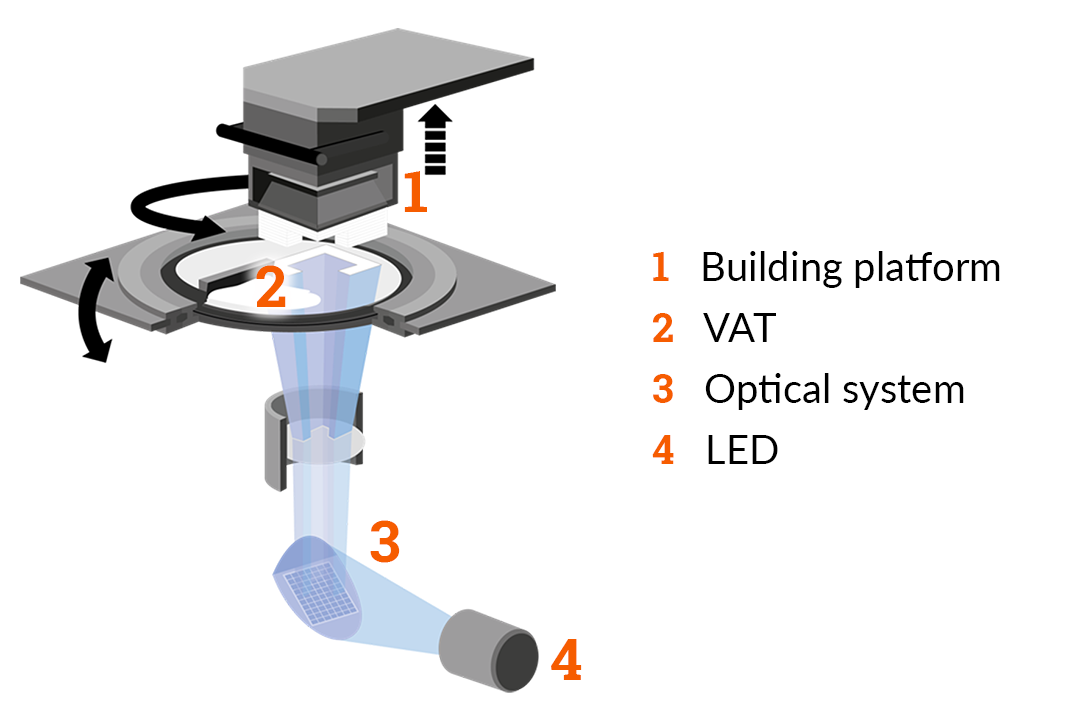

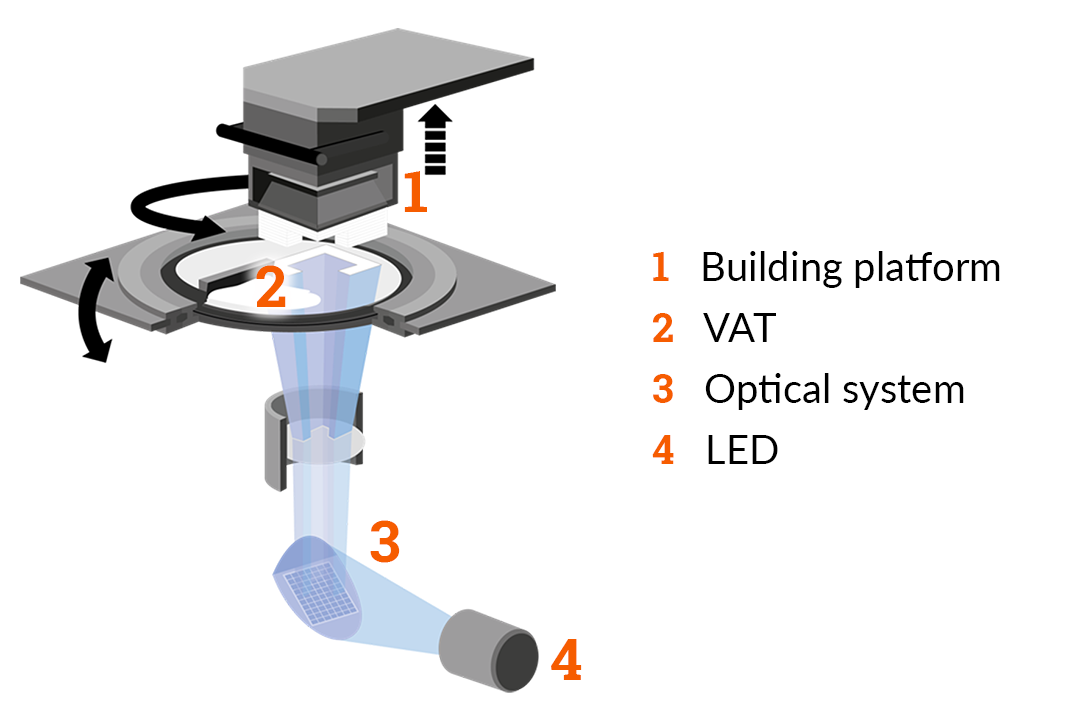

CADdent uses the advanced LCM process (Lithography-based Ceramic Manufacturing) from Lithoz for the 3D printing of ceramics. This process enables the precise and efficient production of complex ceramic components.

The LCM process works with a mixture of liquid polymer and fine ceramic particles. This mixture is applied to a translucent tank. A build plate is immersed in the material and an LED module illuminates the layer from below with blue light, causing the material to harden in the exposed areas. The desired component is created layer by layer. After the printing process, the so-called "green bodies" must be debinded and sintered. In this thermal process, the polymer content is removed and the component is sintered into a dense ceramic.

Advantages of LCM technology

Advantages of LCM technology

Ceramic components manufactured using LCM technology achieve a density of over 99% and a surface quality of less than 1.0 µm. This technology enables the production of highly complex structures with high precision. Aluminum oxide, for example, enables wall thicknesses of 0.15 mm and drill holes with diameters of 0.15 mm with tolerances of around 50 µm.

Properties of ATZ

ATZ (Alumina Toughened Zirconia) is an innovative ceramic that consists of approximately 80% zirconium dioxide and 20% aluminum oxide. This combination optimizes the respective strengths of both materials.

Due to the aluminum oxide content, ATZ is harder and lighter than pure zirconia. It has a very low thermal conductivity and enables more precise and thinner wall thicknesses of 0.15 mm as well as more precise channels. Compared to zirconia, ATZ can also be used to produce significantly thicker walls. While zirconium tends to crack at wall thicknesses of over one millimeter, wall thicknesses of over ten millimeters can be achieved with ATZ. This is due to the more efficient degassing during the debinding process. ATZ is therefore not only more robust, but also more cost-effective to manufacture.

Use the advantages of ATZ for your next project now

ATZ offers numerous advantages over zirconium and is ideal for use in a wide range of industrial applications such as aerospace, electrical engineering and the automotive industry. CADdent, as an innovative service provider in the field of 3D printing and milling, supports you in the realization of your projects with ATZ or other ceramics as well as various metals and plastics.

More News

Are your 3D files ready?

Just upload your data. All files are automatically checked and optimized for printing.

Deutsch

Deutsch English

English Italiano

Italiano

.jpg)

Precision through LCM process

Precision through LCM process Advantages of LCM technology

Advantages of LCM technology