Material Innovation: PROTIQ enables Additive Manufacturing with 100% Pure Copper

PROTIQ now offers additive manufacturing with pure copper, opening up new potential for its customers in the field of mechanical and plant engineering. In 2013, the 3D printing experts from Blomberg already achieved a coup by processing highly conductive RS copper. With the new material, the company is setting another milestone.

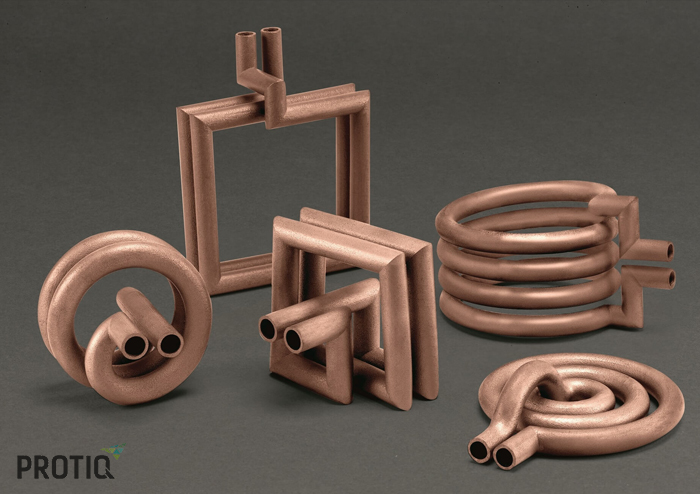

3D Printing with Pure Copper using a Unique Process

Thanks to the development of a special process, PROTIQ is now the first and so far only 3D printing service provider able to process 100% pure copper using additive manufacturing. The new material in the Blomberg-based company's repertoire boasts impressive values: With an electrical conductivity of 100% IACS and a density of 8.9 g/cm³, it puts conventional additively processed alloys in the shade in terms of quality and efficiency. PROTIQ thus enables its customers even more flexibility from now on.

Inducers to the Highest Industry Standards

Machine and plant manufacturers in particular benefit from the new material. They use inductors for the surface hardening of components. This process is more efficient the better the inductor matches the shape of the workpiece to be hardened and the more conductive it is. Additive manufacturing allows the inductor to be customized and precisely adapted within a few days. By using highly conductive copper, PROTIQ can produce inductors to the highest industry standards. The same applies to heat conductors, whose efficiency also depends on the conductivity of their material.

Highly Conductive Copper as an Advantageous Alternative

For the production of inductors and heat exchangers, 3D printing has long been established as a manufacturing process. Classically, various copper alloys are used for processing. Because copper reflects the radiation of conventional laser melting systems, mixtures with a low copper content are often used, which in turn impairs their conductivity. Thanks to PROTIQ's ability to process 100% pure copper, this impairment is now a thing of the past.

Create your individual product in our online configurator now!

DX_PRESS_WEITERE

-

22.04.2024

PROTIQ Marketplace revolutionizes the ordering process for industrial parts with visualization

Read message › -

14.02.2024

Promising cooperation: HP's white Multi Jet Fusion printing now available at PROTIQ

Read message ›

Deutsch

Deutsch English

English Italiano

Italiano