LUPEON: technical materials for special applications

New merchant on the PROTIQ Marketplace

Lupeon is an engineering company founded in 2013 specialized in the development of innovative solutions through Additive Manufacturing in metal and plastic materials for the manufacture of functional parts, offering services from unit manufacturing to serial production. In addition to the manufacturing service, Lupeon's engineering team offers advice on 3D designs in order to take full advantage of 3D printing.

Available materials

From now on, Lupeon offers the following technical materials to the PROTIQ Marketplace customers:

PA11 BLUE FDA

PA11 BLUE FDA is a polymer specially designed for the manufacture of components in the food sector. One of the usual requirements for components that are going to be in direct food contact is that these component are made in blue, so that they can be easily detected visually.

This material complies with EU Commission Regulation No. 10/2011 and FDA 21 CFR, for use in contact with food.

3D printed with SLS technology in PA11 BLUE FDA, the parts can be post-processed with chemical smoothing to homogenize the surface and reduce its surface roughness, thus reduce the adherence of dirt and facilitate the cleaning process. The image shows a part with a standard finish (blasting) on the left and one with smoothing on the right.

PA11 MDT FDA

The PA11 MDT FDA material is a composite formed by a polyamide 11 matrix to which detectable particles are added, allowing the components manufactured with this material to be detectable by X-ray equipment and by magnetic metal detection equipment. These properties make the material ideal for manufacturing components for food processing lines in which the final product has to be scanned by X-ray or metal detection.

This material, like PA 11 BLUE, also complies with EU Commission Regulation No. 10/2011 and FDA 21 CFR, for use in contact with food.

Also PA11 MDT FDA parts are 3D printed with SLS technology and can be post-processed with chemical smoothing to reduce surface roughness. This image shows components with standard finishing (basting) on the left and with smoothing on the right.

STEEL 1.2343 (H11)

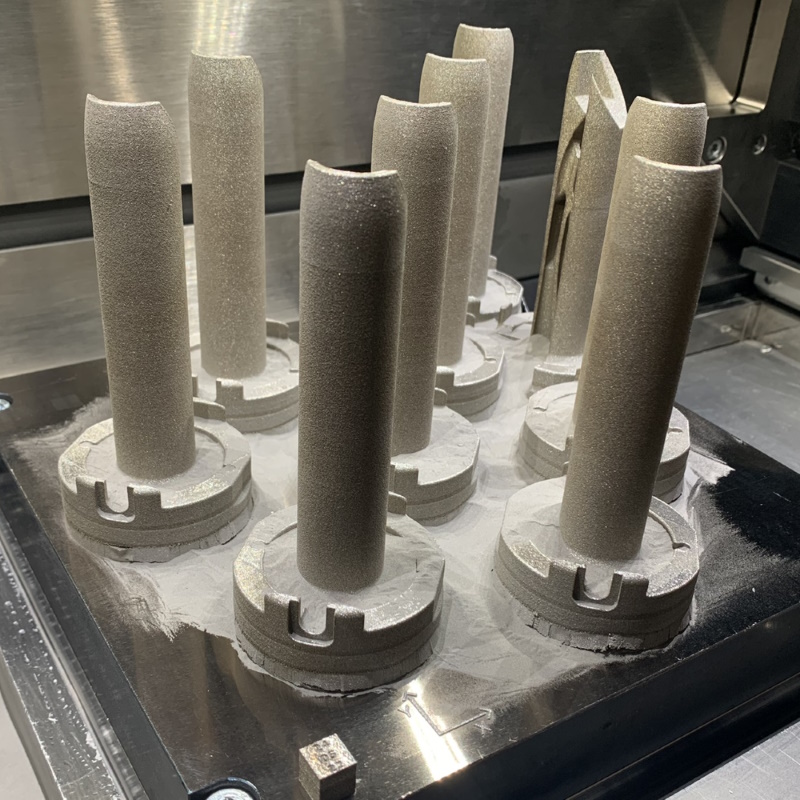

Steel 1.2343 or also called H11 is a material frequently used for the conventional manufacture of inserts for molds. This material is used in plastic injection molds but also in casting molds for aluminum and other metals, thanks to its excellent properties in high temperature conditions.

Additive manufacturing allows Lupeon to manufacture inserts with complex internal cooling channels, being able to reach critical points of the mold with cooling. This provides two advantages, the most immediate to assess is the reduction of the injection cycle time. And secondly, the reduction of quality defects in the injected parts. Given that when reaching the critical points of the mold with refrigeration, the appearance of defects is minimized.

Lupeon has developed different heat treatments after printing in H11, which allows them to adjust the hardness of the material in a range between 45 and 55 HRC (depending on the requirements of each application).

Lupeon supports its customers' growth

Lupeon has years of experience in the use and application of additive manufacturing technology, which allows them to support their clients at all stages of the project development process until obtaining the most efficient solution that provides the greatest value added possible. In this way, Lupeon helps their clients to improve the efficiency of their processes and/or products, thus supports their growth.

More News

Are your 3D files ready?

Just upload your data. All files are automatically checked and optimized for printing.

Deutsch

Deutsch English

English Italiano

Italiano