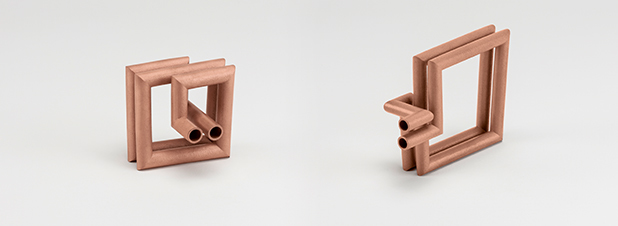

Induction heating with custom copper inductors

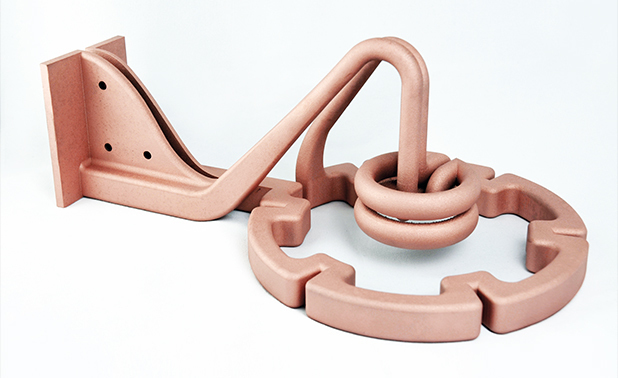

In induction heating, precision-fit inductors made of copper are required for processing different component shapes. Until now, these have mostly been manufactured by hand in complex processes. At PROTIQ Marketplace, we produce your individual induction coils quickly and cost-effectively using 3D printing. This allows you to benefit from reduced delivery times, greater design freedom and a longer coil life.

We are happy to manufacture your existing coil design, according to specified 3D CAD data. Simply upload the coil geometry via the upload button and order the production in just a few steps. Simple coils, for which you do not yet have 3D data, can be easily created yourself with our innovative inductor configurator and ordered immediately. CAD or design experience is not required here. For complex coil shapes that are not represented by the configurator, our CAD engineers will be happy to create a 3D model for you, based on your technical drawing. Please ask for an offer.

What is induction heating?

Induction heating is a widely used industrial heating process. In this process, a workpiece made of electrically conductive material (for example, steel or cast iron) is placed in the magnetic field of an induction coil - the inductor - and heated in a very short time. Strong alternating currents are used to generate the magnetic field, so that the coils are cooled from the inside with cooling water. For this reason, inductors are usually designed to be hollow. In contrast to processes in which heat is generated by a furnace or flame, the heat in induction heating is generated directly in the component. This results in a very efficient process and high efficiency compared to other methods. Furthermore, the heating process can be very precisely controlled and reliably reproduced via the current intensity and the generator frequency. These factors have made induction heating the standard in many industrial applications.

In the surface hardening of highly stressed components, such as transmission components in automobiles, induction heating is a widely used standard. Precise, local heating followed by abrupt cooling increases the hardness and strength of the component surface.

In induction brazing, two components are precisely heated and joined by means of a brazing material. The heat required for the joining process is generated by an inductor. Precise, homogeneous heating to the target temperature is crucial for the quality of the joint. Components that are given their geometry with the aid of hot forming must be heated before machining. Here, a precise inductor offers the advantage that the heating only takes place locally at the required points.

The inductor - the heart of the induction heating process

The shape of an inductor is directly related to process accuracy, because heat is generated only at the points where the electromagnetic eddy currents are induced into the workpiece. Thus, the more precisely the inductor is matched to the geometry of the component to be heated, the more precisely the heat distribution can be controlled. For this reason, an individually developed inductor is required for each design.

- Cost-effective production of individual geometries

- Increased design freedom

- Precise fit and true-to-data implementation

- Short delivery times thanks to tool-free production

- Longer service life of the coils

Advantages of 3D-printed inductors

Why 3D-printed inductors?

Traditionally, copper inductors get their shape by hand bending or soldering, which is why only relatively simple geometries can be produced due to the process. The manual manufacturing process is also very time-consuming. With frequently changing workpieces, companies have to accept correspondingly high costs for the purchase of new inductors. At the same time, the manually manufactured coils show only low repeatability due to the manual manufacturing process.

Alternatively, more complex inductors are CNC-milled from the solid. In order to create the required cooling channels, the individual components must be joined by welding or soldering. This process is also lengthy and cost-intensive. At the same time, these joints represent a weak point in later operation and a potential source of failures.

3D-printed inductors from PROTIQ offer many advantages

PROTIQ's inductors are manufactured using the additive manufacturing process of selective laser melting. In this process, metal components are created directly from CAD data and without the use of additional tools. This allows the coils to be automated and manufactured directly in one piece. This eliminates the need for expensive manual production. The avoidance of soldered seams also ensures an increased service life and longer coil life.

The result is highly conductive and durable inductors that exactly match the specified dimensions - a level of precision that is virtually impossible to achieve by conventional means. Thanks to additive manufacturing, even individual and complex geometries can be realized within a few days.

Inducters from PROTIQ - fast and digital order processing

In industrial 3D printing with copper, the time and cost involved in producing a custom inductor can be effectively reduced. The end-to-end digital business process of PROTIQ Marketplace saves valuable time already during the ordering process. After uploading the inducer geometry, you can obtain an automatically generated quote and trigger the order within a few clicks. If you do not yet have 3D data of the coil, you can put it together quickly and intuitively with the inductor configurator, entirely according to your individual specifications. The configuration is based on the modular principle and takes into account the special requirements of industrial customers. Production can start immediately after receipt of order and you will receive the coils within a few days.

Special shapes and simulation-based optimization

In addition to the versatile design options of the inductor configurator, the PROTIQ Marketplace can also be used to manufacture copper inductors in special shapes for unusual areas of application. With its great expertise in simulation-based optimization, the PROTIQ team is also your contact for the analysis and optimization of your established induction heating processes. We would be pleased to prepare a quotation for you, tailored to your individual applications and processes.

Deutsch

Deutsch English

English Italiano

Italiano