How to create a 3D file

With today's technical possibilities, creating a 3D file is easier than ever and by no means reserved for professionals. With the right tools, anyone can create files for 3D printing and more.Building 3D Files Manually

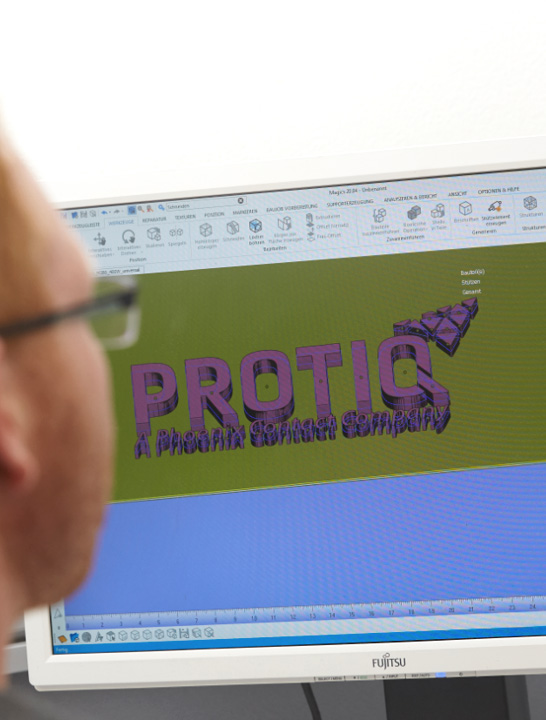

For an idea to become a three-dimensional object, its shape must be created from scratch in a CAD program. The visualization is done by a complex construction of the object from numerous facets, polygon lines or interconnected points. The more accurately the 3D file is to depict curved surfaces, for example, the more facets or points the 3D file will contain.

- A CAD program is essential when creating 3D data. In addition to software for professional use, there are also a number of freeware programs that can be used to create good quality data.

- For beginners in the world of 3D design, home programs such as Blender or Sculptris are a good choice. Even newer versions of Adobe Photoshop have functions for creating 3D files.

- Especially for beginners, it can also be practical to download ready-made 3D printer templates and customize them according to your own wishes. 3D printer templates can be downloaded from many platforms free of charge or at a low price.

- Anyone who works professionally with 3D files needs a comprehensive software solution that can be expanded as needed. In addition, there are documentation options and authentic simulations. Professional CAD programs such as Creo Parametric, Siemens NX, SolidWorks, AutoCAD or Catia meet those requirements.

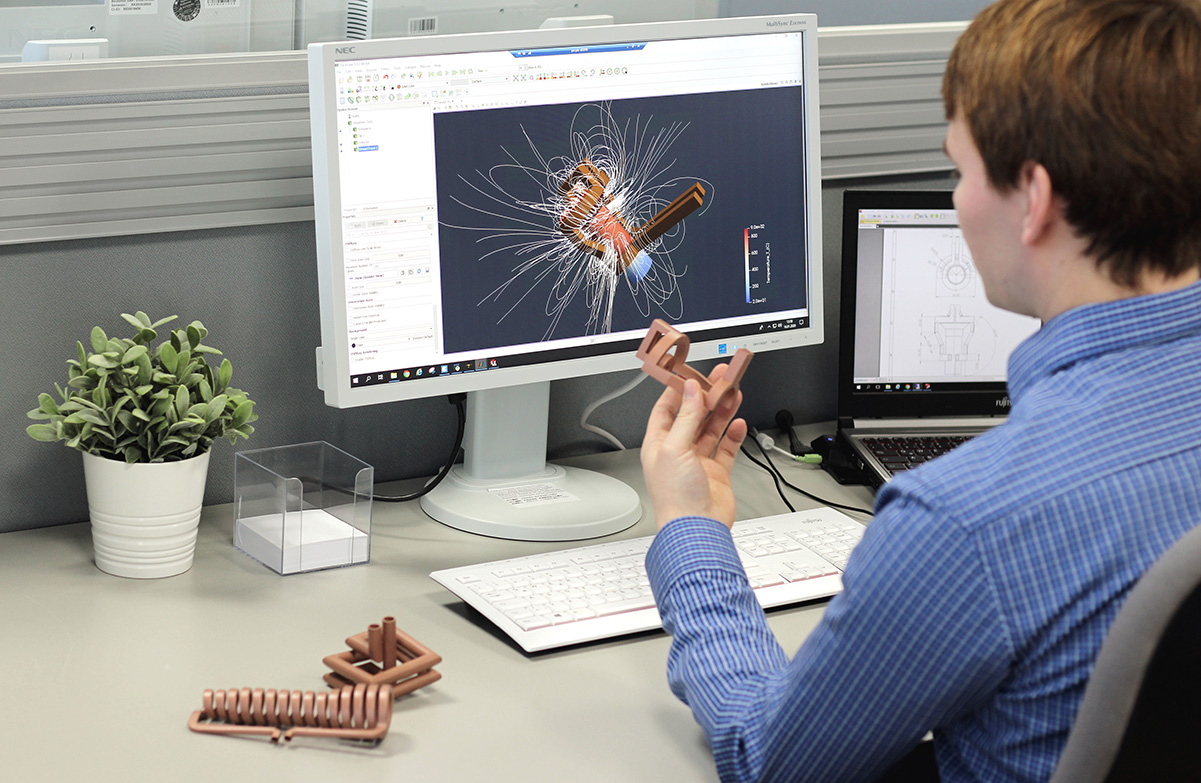

File Creation with 3D Scanning

There are various motives for the creation of 3D data of an existing object. In addition to the industrial reproduction of handmade models, lost data or subsequently modified objects are also good reasons to generate the required data by means of scanning. This process is called "Reverse Engineering".

There are different forms of 3D scanning, differing both in their technology and in the equipment used.

- Mobile optical 3D scanners can create three-dimensional images of objects in a short time. Even certain smartphone apps allow the scanning of objects with the help of the smartphone camera.

- Higher quality optical scanners work with the use of lasers or a combination of multiple cameras and projected black and white stripes.

- Optical-based scans capture only the external shape of an object.

- For professional purposes, stationary 3D scanners are preferable because they work more accurately.

- With the use of computed tomography, objects made of a single material can be scanned holistically. In this way, internal structures are also mapped in addition to the outside.

- Computed tomography is the most precise method for 3D scanning.

Request a CT scan now

We create the 3D files of your object. Contact us for more information!

Request nowDesign Notes for 3D Files

Especially during the first projects with 3D files, errors can occur that have a negative impacts on the result of additive manufacturing. The most common types of inconsistencies include:

- The 3D model contains open edges and does not form a closed volume.

- Variations caused by conversion of different 3D file formats.

- Inaccurate 3D scan, as performed with a simple handheld scanner or smartphone.

- A mix of materials and colors that cannot be differentiated in the scan.

- The 3D file contains objects with sharp corners or edges. Also flat curvatures and slopes cannot be realized in all fineness.

- The 3D model contains details that are too delicate, or wall thicknesses that are too thin, which cannot be reproduced by the selected manufacturing process.

- Tolerances are not taken into account and the finished object does not have the desired size.

You can find more design notes for 3D print files here.

3D Files for Laser Sintering and Laser Melting

Laser sintering and laser melting are forming processes that involve strong heating of the material to be formed. Since these operations are accompanied by large temperature fluctuations, the shrinkage of the formed material, for example, must be taken into account in the creation of the 3D files.

Design recommendations for selective laser sintering can be found here.

You can download design recommendations for selective laser melting here.

Create 3D Files in the Correct Format

In order for the created 3D file to be processed further and adapted by the service provider if necessary, it must be exported in a common file format that stores all relevant information.

The most common file formats for 3D printing are:

- STL (Standard Triangulation Language/Standard Tessellation Language)

- OBJ

- STEP (Standard for the Exchange of Product model data)

Which file format is suitable for the planned project depends on the individual requirements.

3D printer templates

3D printer templates, often saved as STL files, contain all the necessary information to build an object layer by layer. The creation of such templates requires both technical knowledge and creative skills. Designers use specialized software such as Tinkercad, Blender or Fusion 360 to create detailed and precise models. These templates can then be shared on platforms such as Thingiverse or Printables, where they can be downloaded and printed by other users. The variety of 3D printer templates available is impressive, ranging from simple everyday objects such as cell phone cases and key rings to complex mechanical parts and artistic sculptures. For beginners, these templates offer an excellent way to familiarize themselves with 3D printing without having to create models themselves. At the same time, they allow experienced users to refine and share their own designs. Using 3D printer templates saves time and resources, as they are often already optimized and thus facilitate the printing process. Overall, 3D printer templates contribute significantly to the democratization of 3D printing technology by providing access to high-quality design-in for everyone.

Deutsch

Deutsch English

English Italiano

Italiano