3D printing for model making

Why 3D printing in model making?

Model making thrives on attention to detail and precision. Whether architectural models, miniatures for tabletop games or technical prototypes - the requirements for customized components are high. Model makers often reach their limits with conventional production methods: Manual modeling is time-consuming, traditional casting processes require expensive molds, and not every component can be easily manufactured.

This is where 3D printing comes into play. Modern additive manufacturing technologies make it possible to produce even complex models with the highest level of detail - quickly, efficiently and without expensive tooling costs. This opens up completely new possibilities for model makers in particular:

- Have individual components manufactured according to your own designs

- Highest precision even with intricate structures

- Variety of materials to suit the respective requirements

- Fast production without long lead times

Advantages of 3D printing for model making

3D printing opens up completely new possibilities for model makers. Thanks to additive manufacturing, customized components can be produced with maximum precision - without complex tools or manual post-processing. This not only saves time, but also enables designs that would be almost impossible to realize using traditional methods.

Tailor-made components for every project

Model making thrives on individuality. Whether unique miniatures, intricate architectural models or functional technical components - with 3D printing, you can implement your own designs exactly as you wish. Hardly any model is too complex, hardly any shape too elaborate.

Maximum precision for the finest details

Thanks to modern processes such as stereolithography (SLA) and selective laser sintering (SLS), even the finest structures can be realized. 3D printing is the perfect solution for miniatures, dioramas and detailed architectural models in particular.

Variety of materials for different requirements

Depending on the project, different material properties are required. Whether highly detailed plastic components, heat-resistant components or even metal parts - with 3D printing, materials can be selected specifically for the respective application.

Fast, efficient and cost-saving

While classic model building methods often require tedious manual work or expensive tools, 3D printing offers an enormous advantage:

- No casting molds or milling tools required

- Fast production - perfect for prototypes or small series

- On-demand production, exactly as required

Complex geometries without limits

With 3D printing, even complicated cavities, organic shapes and moving parts are no problem. Model makers can implement completely new designs that would be difficult or impossible to produce using conventional methods.

Whether detailed miniatures, intricate architectural models or functional metal parts - 3D printing is the future of model making.

Which 3D printing processes are best for model makers?

Depending on the model building project, different 3D printing technologies are required. While high-resolution miniatures require extreme attention to detail, stability and functionality are crucial for mechanical components. The three best-known additive processes for professional model making are stereolithography (SLA), selective laser sintering (SLS) and selective laser melting (SLM).

Stereolithography - perfect for the finest details

Ideal for: Miniatures, dioramas, architectural models

Advantages

• Highest level of detail for the finest structures

• Extremely smooth surfaces

• Perfect for intricate model components

Selective laser sintering - for stable and complex models

Ideal for: Technical prototypes, functional model components, complex geometries

Advantages

• High stability and resilient components

• No support structures required → more design freedom

• Very suitable for mechanical and functional models

Selective laser melting - metal 3D printing for robust components

Ideal for: Structural parts, mechanical components, durable model parts

Advantages

• High-strength and resilient metal parts

• Perfect for functional model making applications

• Aluminum and stainless steel available for durable components

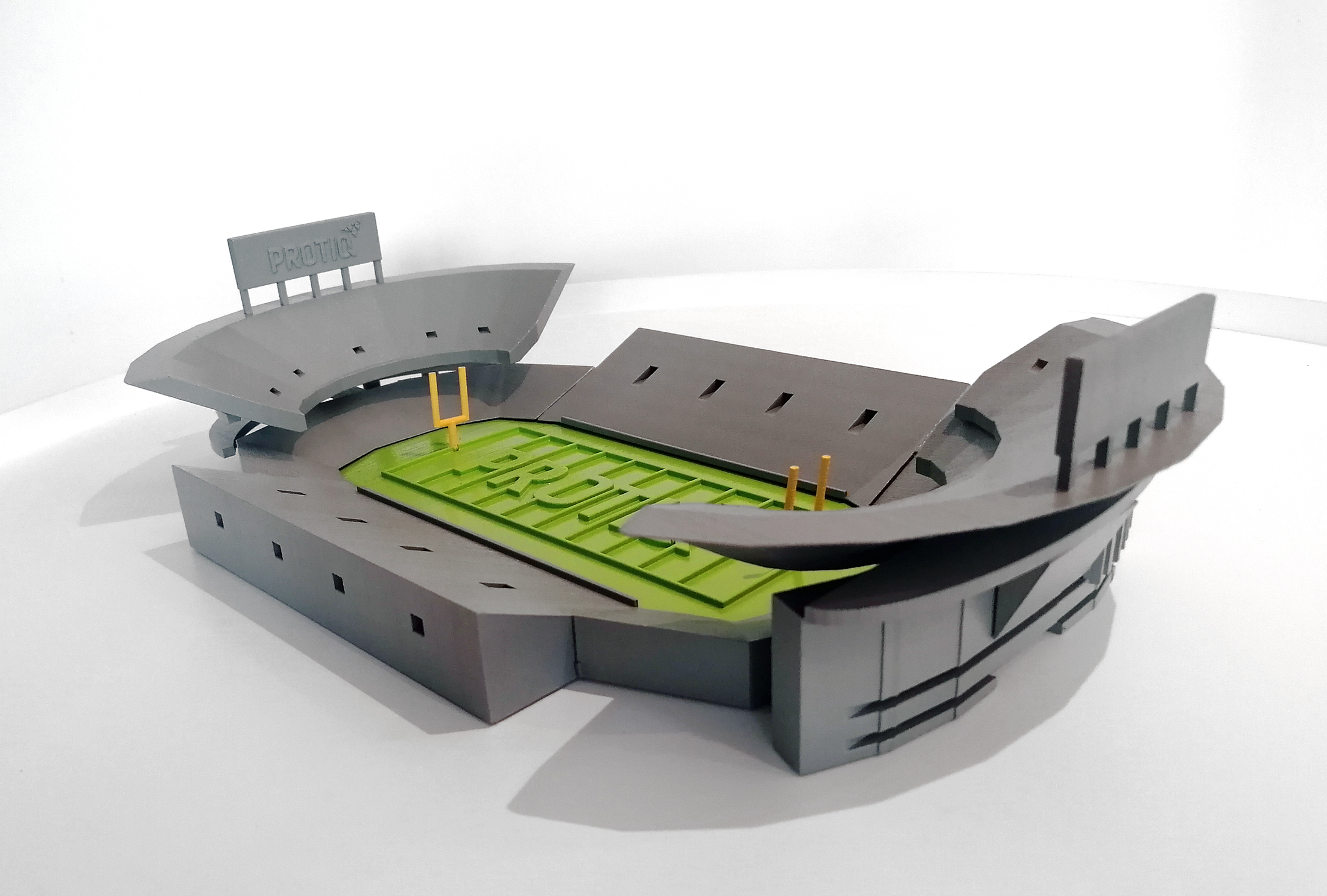

3D-printed model making projects

3D printing can be used to realize model making projects that would be difficult or very costly to implement using conventional methods. The combination of high-precision printing processes and a wide variety of materials makes 3D printing the perfect solution for detailed miniatures, complex architectural models and functional components.

Miniatures and dioramas for tabletop games

Tabletop and model game fans rely on the highest precision - 3D printing can be used to produce detailed miniatures, figures and backdrops in a quality that classic casting processes cannot achieve.

Application examples: Character models for Warhammer, D&D & Co, miniature terrain and dioramas with intricate structures, individual replacement parts for damaged game figures

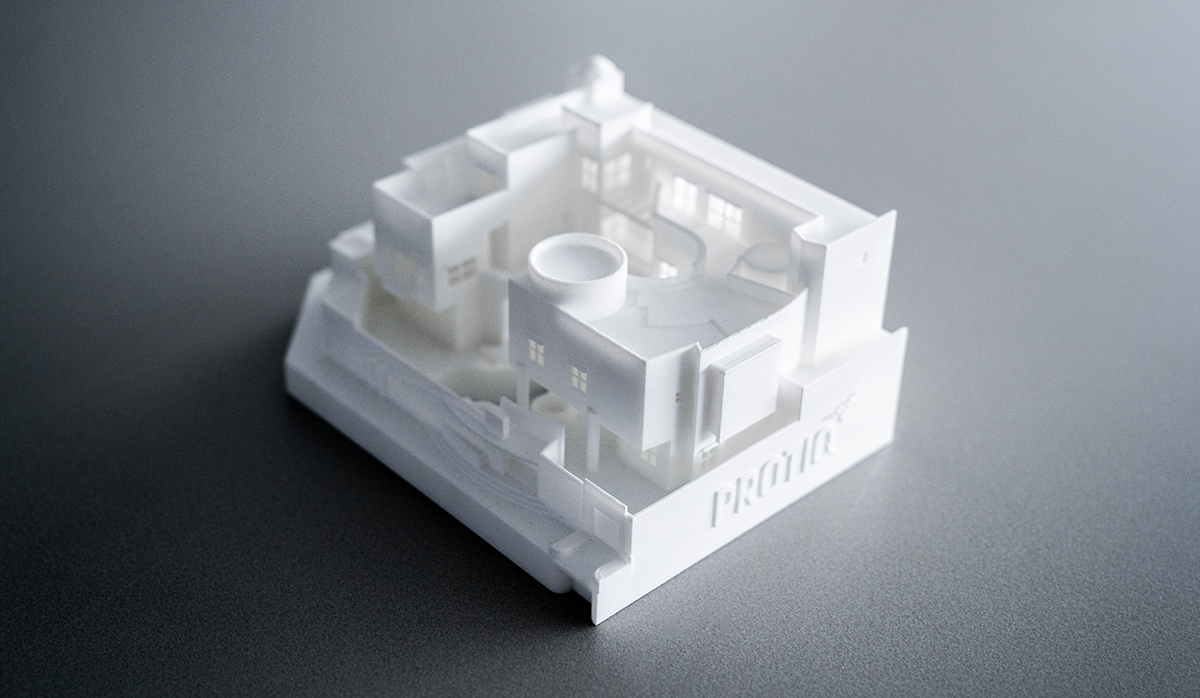

Architectural models - precise and realistic

3D printing enables detailed architectural models that realistically represent building plans. Intricate structures, façade details and transparent windows in particular benefit from additive manufacturing.

Application examples: Concept models for architects and urban planners, detailed building structures with windows and balconies, presentation models for construction projects

Model vehicles - high-quality components for vehicle model making

Whether cars, airplanes or trains - 3D printing offers model makers the opportunity to produce high-precision components for realistic replicas. Metal 3D printing (SLM) in particular is ideal for components that require stability and resilience.

Application examples: Individual vehicle parts for RC cars, model airplanes and trains, Functional components for mechanics such as chassis and hinges, High-quality metal components for durable model vehicles

How the ordering process works on the PROTIQ Marketplace for model making projects

With the PROTIQ Marketplace, you can easily order your individual model components online - in just a few steps and with professional production quality. Whether you need a high-precision miniature, an architectural model or a technical component - the ordering process on the PROTIQ Marketplace is fast, intuitive and transparent.

Upload 3D model

Upload your 3D model in a common file format, e.g. STL, STEP or OBJ. If you do not yet have a 3D model, you can create one using CAD software, download models from corresponding platforms or adapt existing models.

Select material and process

Depending on the requirements of your project, you can select the optimum material and printing process.

Complete your order and start production

Have you selected the material and process? Then you can complete the order directly.

Why 3D printing is a real revolution in model making

- Customized designs without expensive tools

- Finest details for miniatures & architectural models

- Functional components for vehicle models and prototypes

- Fast and precise production for small series or individual pieces

3D printing in model making is a real revolution, as it enables individual design-in without expensive tools and delivers the finest details for miniatures and architectural models. This technology allows model makers to create complex structures and intricate details that would be difficult to achieve using traditional methods. In addition, functional components for vehicle models and prototypes can be produced quickly and precisely, which is particularly advantageous for small series or individual pieces.

3D printing also offers the opportunity to react quickly to design changes and create prototypes in the shortest possible time. The PROTIQ Marketplace offers the perfect solution for model makers who need high-precision and customized parts by providing a platform for easy access to professional 3D printing services. This allows model makers to realize their creative ideas efficiently and cost-effectively.

The future of model making with 3D printing

Model making is constantly evolving - and 3D printing plays a central role in this. Whether detailed miniatures, realistic architectural models or functional components for technical constructions: The possibilities of additive manufacturing are almost limitless.

Thanks to modern 3D printing processes such as SLA, SLS and SLM, models can be created that would either be impossible or extremely costly using traditional methods. Model makers benefit from numerous advantages:

- Unlimited design freedom: No casting, no molds - just limitless creativity

- Wide range of materials: From highly detailed acrylic resin to robust metal

- Fast production: No waiting for long tool or production times

- Economical production: Comparatively low costs for small quantities

Whether you are working on a one-off prototype or a small series - with 3D printing you can have high-quality model components manufactured individually.

The PROTIQ Marketplace makes this process even easier: upload, select material, order - done! Our reliable manufacturing service providers ensure that your model is produced to the highest quality.

Take your model making to the next level - order your individual component on the PROTIQ Marketplace now!

How sustainable is model making with 3D printing?

3D printing conserves resources as only the required material is processed. It also eliminates many intermediate steps, which saves energy and material.

Can the models be reworked?

Naturally. We offer various finishing options such as sanding, painting, polishing or assembly - depending on your requirements.

Are movable or functional models also possible?

Yes, moving parts or functional assemblies can also be realized through targeted design.

How does ordering from PROTIQ work?

You upload your CAD data directly to the PROTIQ Marketplace, select the material and process and receive a quote immediately. After approval, we start production.

What materials are available for model making?

We offer a wide range of materials - from plastics such as PA12 or ABS to resins for particularly fine surfaces. We will be happy to advise you on the right choice of material depending on the application.

Deutsch

Deutsch English

English