3D Printed Cutting Guides

The human face is not only functional, but also emotionally important and identity-forming. This makes it all the more serious when it is disfigured by accidents or illness. 3D-printed cutting guides help those affected to regain a sense of normality again.The application

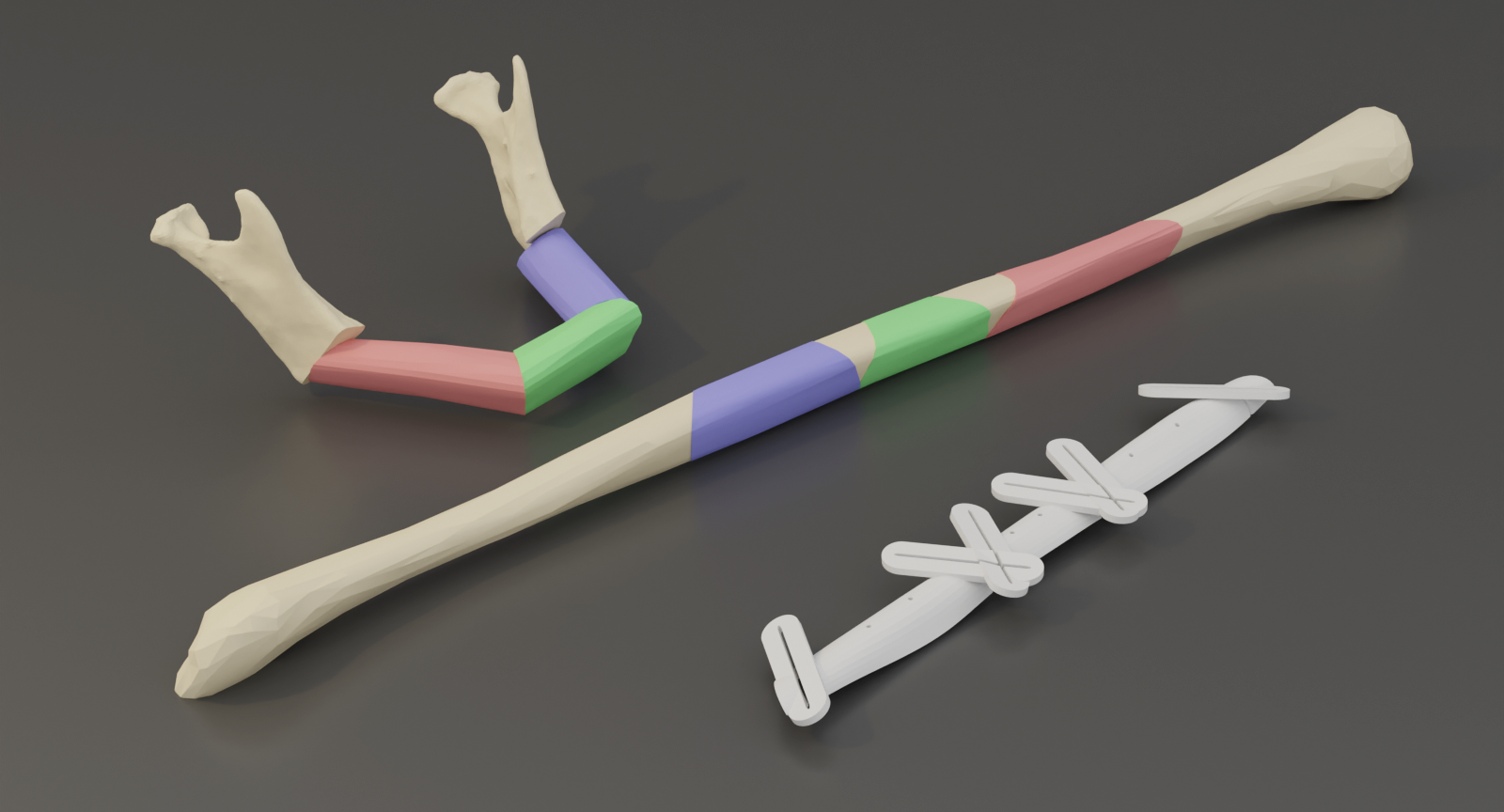

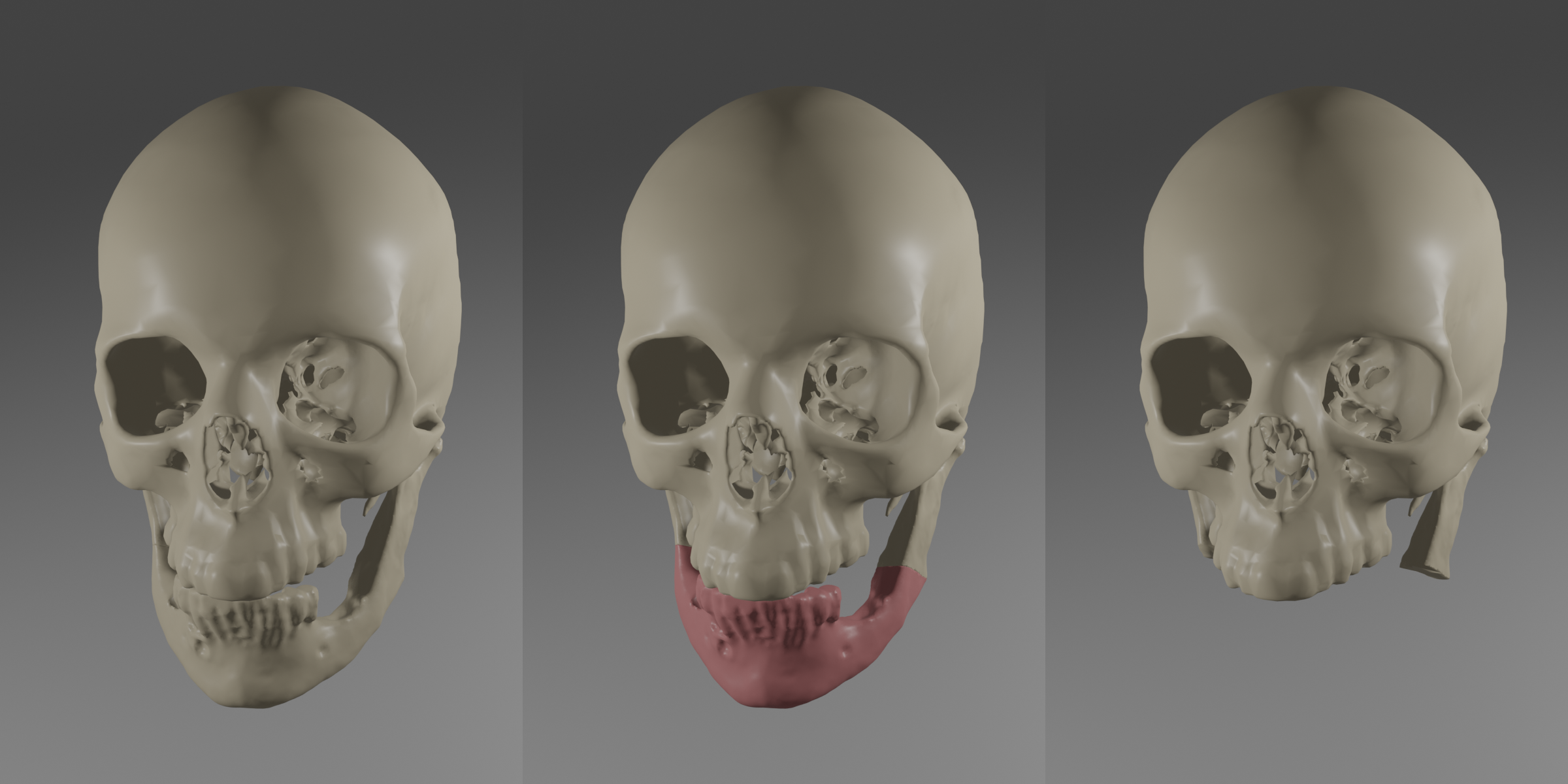

If an inflammation, a tumor or an accident means that parts of the jaw have to be removed, these can be reconstructed using the patient's own body material: The jaw can be remodeled from a fibula. This is precision work, however, because the bone has to be broken down into small pieces and then reassembled at the right angle in a U-shape. Additively manufactured and patient-specific surgical guides can assist in this process.

© Inzipio

© Inzipio

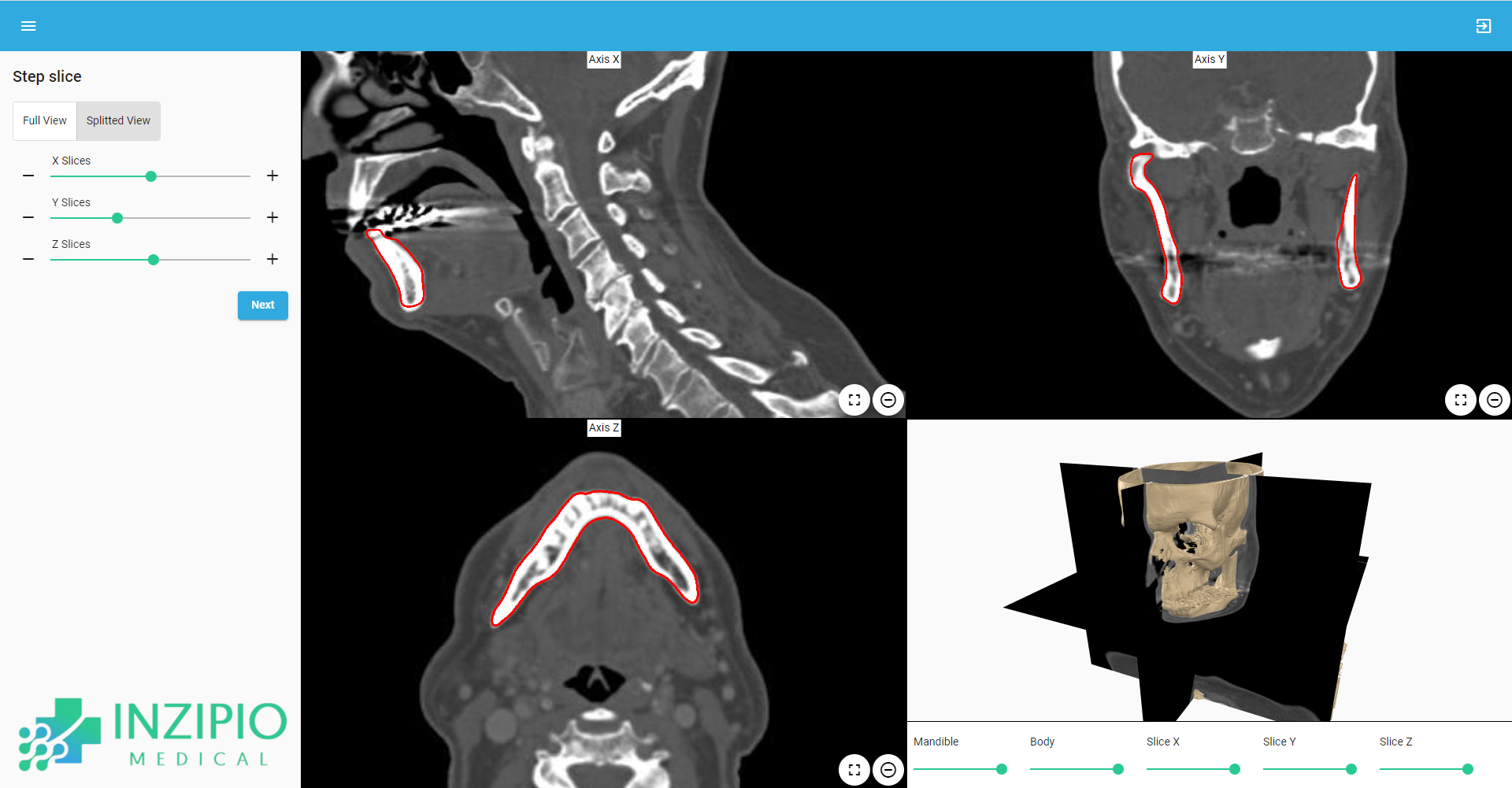

Artificial intelligence and 3D printing in surgical planning

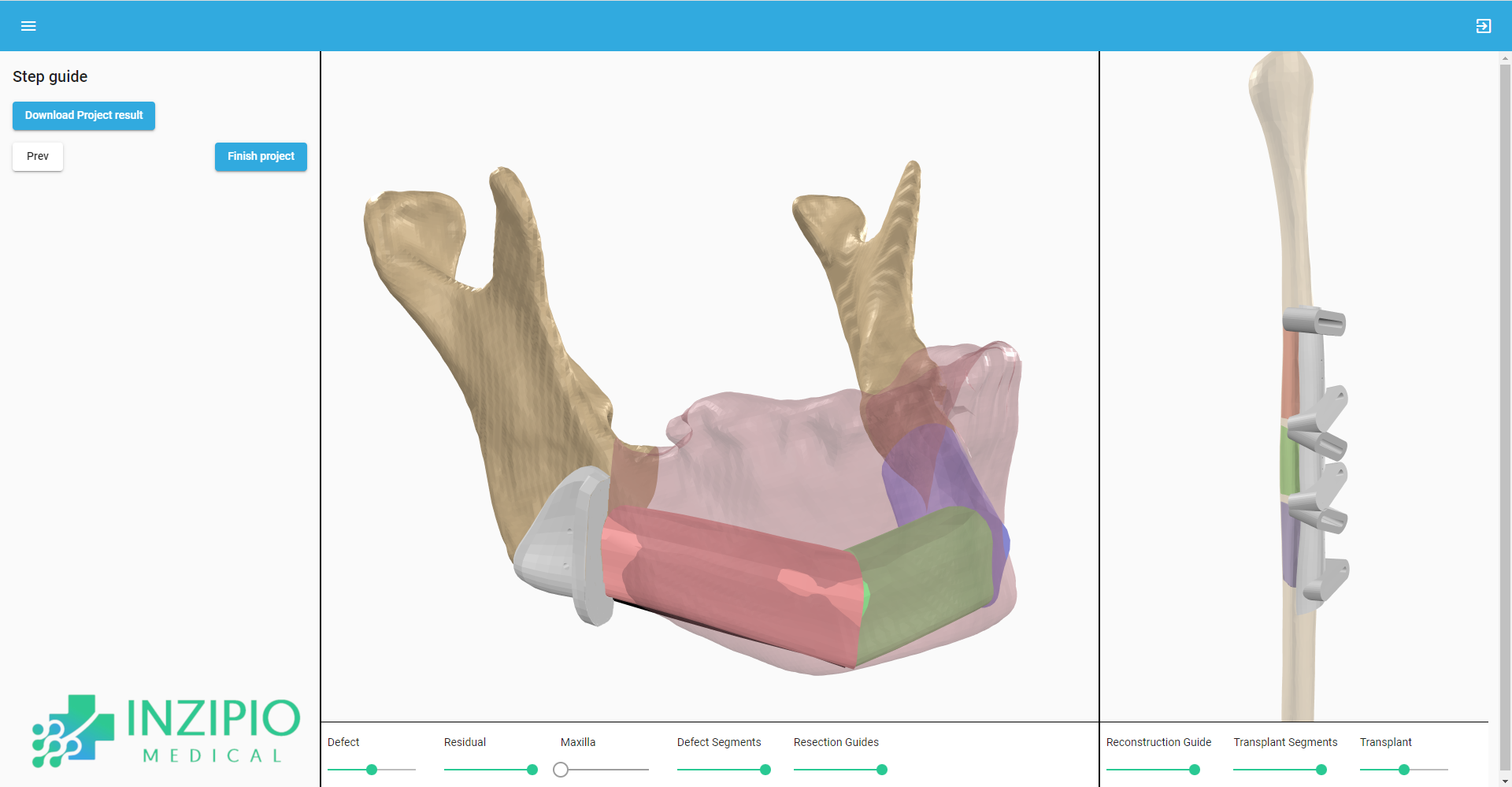

In order to produce the cutting guides, a 3D data set is first required: Inzipio's area of expertise. Inzipio develops medical software for digital surgery planning. The Aachen-based company's software uses CT data to calculate a digital 3D model for surgery planning with the help of artificial intelligence. Fully automated, this creates a proposal for how the jaw of the respective patient could be reconstructed. Doctors can then adapt this model if necessary and generate the final 3D data.

The cutting guides digitally planned by Inzipio can be produced in 3D printing within a very short time - from a batch size of 1 and, in urgent cases, also "overnight". PROTIQ uses the SLS process for this, you can find out more about it here. The components are made of the engineering plastic PA12, can be sterilized and meet the necessary requirements for short-term wound contact.

In the operating room, the guides are screwed onto the fibula and show the surgeon which parts of the bone have to be removed and at which angle of cutting. Later, the individual transplant for the jaw is created from the individual parts.

The combination of digital surgical planning using artificial intelligence by Inzipio, and additive manufacturing by PROTIQ represents a valuable asset for the success and quality of the treatments. Bony microvascular grafts represent the state of the art in oral and maxillofacial surgery, but because of the complexity described above, they are only made possible by the incorporation of innovative technologies.

In the end, it is above all the patients who benefit from the fast and precise process, not only getting back their smile, but also a great deal of quality of life.

Advantages of 3D printing for this use case

Especially when it comes to individual solutions in small quantities, additive manufacturing is the production method of choice. It has benefits that not only enable rapid patient care, but also produce precision-fit components.

Some of these benefits are:

- Precise and automated production of cutting guides

- Tool-free production of patient-specific individual pieces

- Simple adjustments possible in the 3D model

- Short production times

- Material suitable for short-term wound contact

© Inzipio

© Inzipio

About Inzipio

Inzipio is a spin off of the Clinic for Oral and Maxillofacial Surgery at the University Hospital RWTH Aachen and offers a software solution for automated surgery planning.. The virtual planning of facial reconstructions can be performed by surgeons themselves – in a matter of minutes.

Find out more about Inzipio on their webseite inzipio-medical.com

Deutsch

Deutsch English

English