3D-printed knives

3D printing makes it possible to produce knives in a completely new way. Instead of forging the blade from a piece of metal, they can now be printed directly from digital 3D models. This opens up many possibilities for the design and function of knives.What are 3D-printed knives?

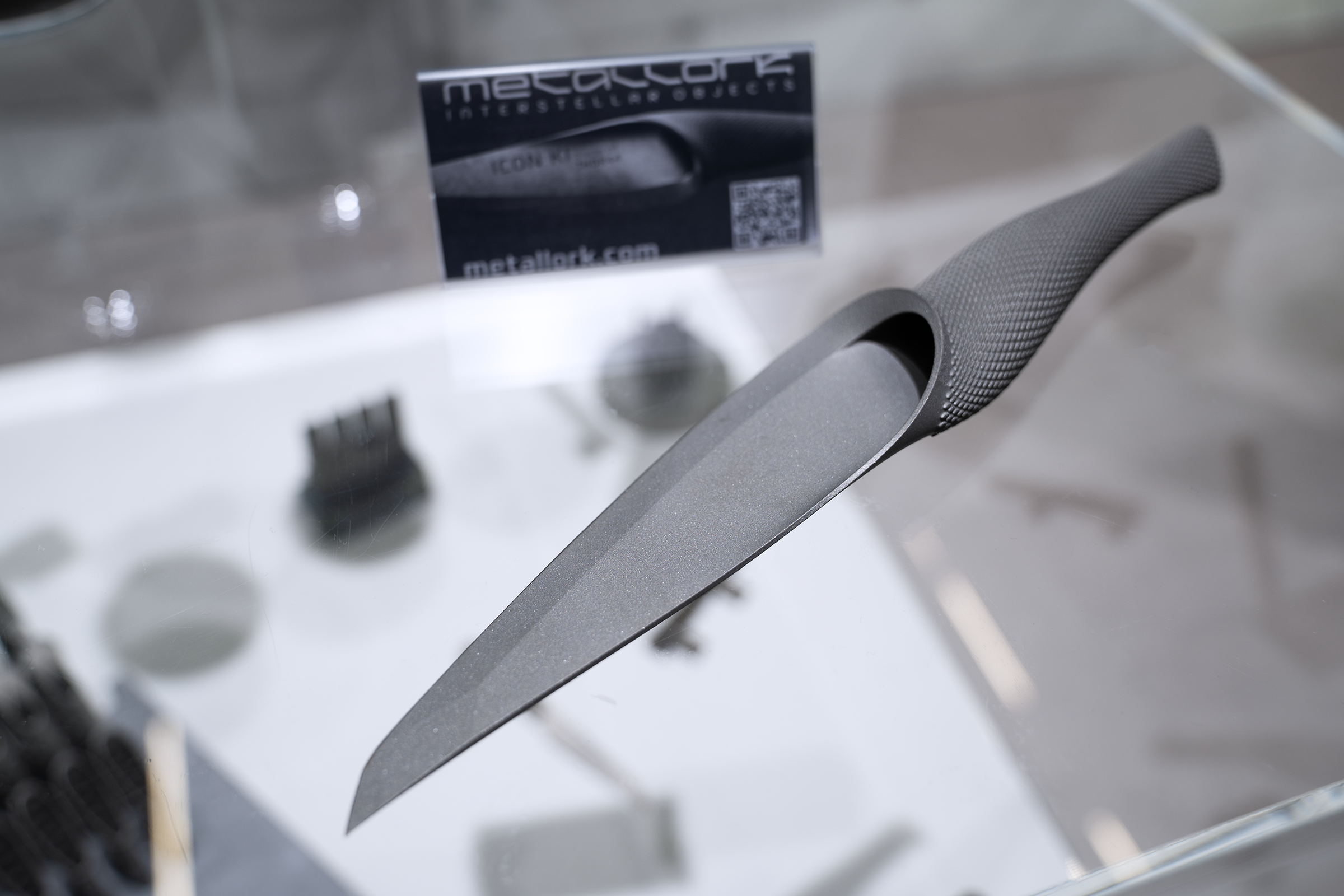

3D printing of knives is still in its infancy and is currently only offered by a few specialized companies. Nevertheless, this technology opens up exciting new possibilities in knife production. By using metal 3D printing, in particular selective laser melting (SLM), knives can be produced with individual designs, integrated structures and special properties. This method makes it possible to produce high-strength, durable and customized knives that would be difficult to implement using conventional manufacturing methods.

3D printing is revolutionizing many industries - from aerospace and machine building to medical technology. But what about the production of cutting tools? We take a look at traditional knife manufacturing methods and show why 3D printing, especially with 440C stainless steel, is a promising alternative.

Traditional knife manufacturing and industrial production

Traditional blacksmithing

For centuries, knives have been made by forging, hardening and sharpening. Hand-forged knives are considered to be of high quality and are characterized by excellent sharpness and durability. However, this method requires manual skill, is time-consuming and difficult to scale.

Advantages

Disadvantages

Industrial knife production

Modern industrial companies mass produce knives by punching, grinding, hardening and assembling individual components. This enables large quantities to be produced quickly and cost-effectively. However, only standard designs are possible here, and individual customizations are not provided for or are very costly.

Advantages

Disadvantages

In comparison, metal 3D printing offers completely new design possibilities. Thanks to selective laser melting (SLM), knives can be manufactured without restrictions in terms of form and function.

3D printing of knives

Selective laser melting

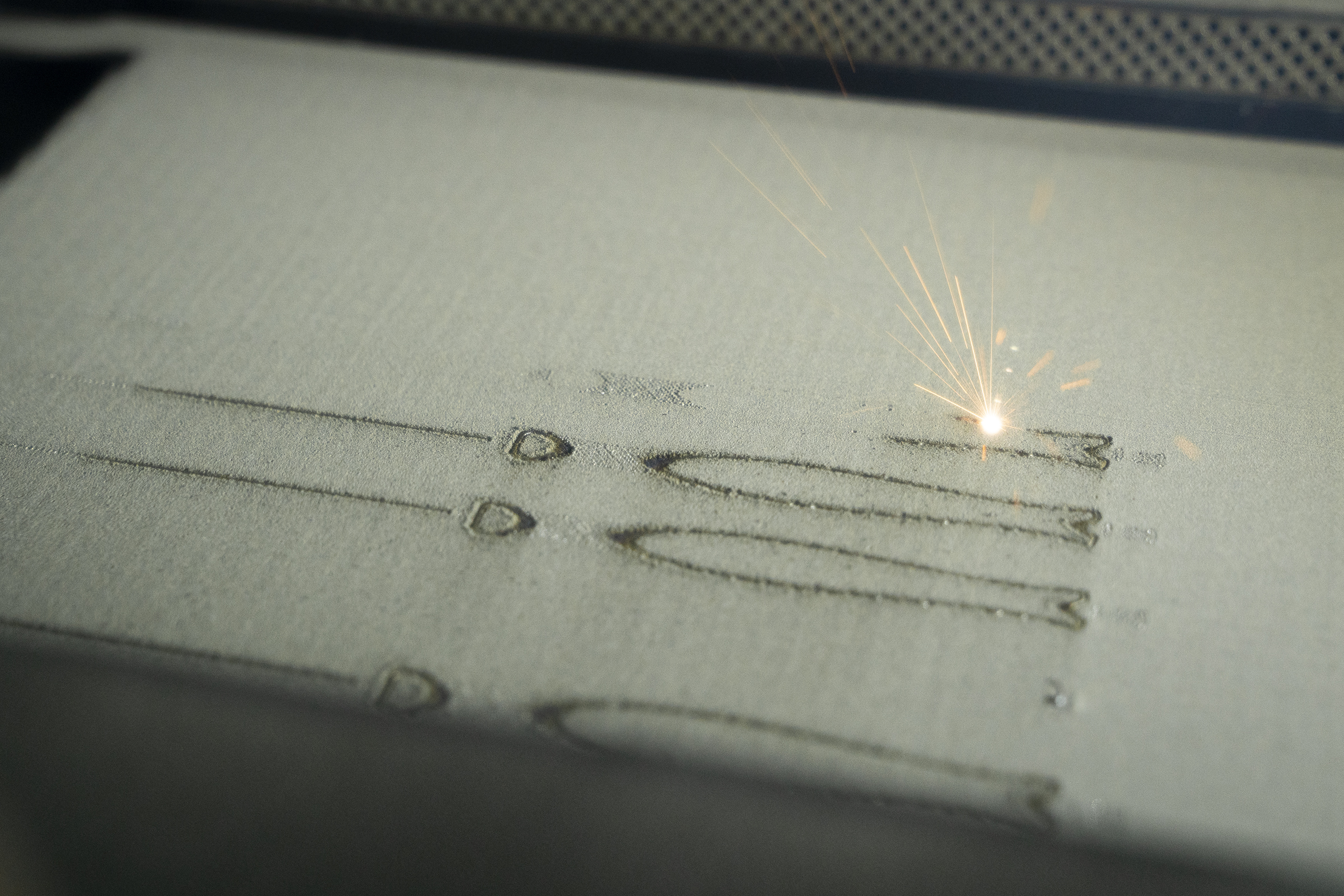

Selective laser melting (SLM) is an additive manufacturing technology that makes it possible to produce knives directly from metal powder. A high-power laser melts the metal powder layer by layer until the complete knife is created. This process allows enormous design freedom, as no traditional machining steps such as forging or milling are required.

Advantages of the SLM process for knife production

440C stainless steel - high-strength knife steel

For the production of 3D-printed knives, we at PROTIQ rely on THOR44, a metal powder based on 440C stainless steel specially developed for additive manufacturing. This material is characterized by its high hardness and excellent wear resistance, which makes it ideal for cutting tools.

Properties of THOR44

High hardness: With an achievable hardness of up to 65 HRC, THOR44 is the hardest tool steel available for the Laser Powder Bed Fusion (LPBF) process.

Corrosion resistance: As a martensitic stainless steel, THOR44 offers excellent resistance to corrosion, which increases the longevity of the knives.

Excellent processability: The material can be excellently processed in the LPBF process and enables the production of complex geometries without high preheating temperatures.

High thermal conductivity: THOR44 has around 50% higher thermal conductivity compared to M300, which leads to improved heat dissipation during use.

Nickel and cobalt free: The material does not contain nickel or cobalt, making it a more environmentally friendly choice.

Areas of application for THOR44

Thanks to its outstanding properties, THOR44 is suitable for a wide range of applications, including

- • Knives and blades

- • Rolling and ball bearings

- • Valve components

- • Gear wheels

- • Molds and injection molding tools

- • Tools for food processing

- • Surgical instruments

By using THOR44 in additive manufacturing, we at PROTIQ can produce customized knives with exceptional hardness and durability that meet the specific requirements of our customers.

Design possibilities

Innovation through 3D printing

Examples of innovative designs

The future of knife production with 3D printing

Collaboration with Asgaard Metals, UG-Tools and Metallork

What is the advantage of 3D-printed knives over forged or industrially manufactured ones?

3D printing enables a completely new level of design freedom. Knives can be manufactured from a single piece - without soldering or welding seams. This results in particularly stable, durable and customizable cutting tools that would be almost impossible to produce using conventional methods.

What materials are used for 3D-printed knives?

PROTIQ uses the specially developed material THOR44, a high-strength stainless steel based on 440C. It offers a hardness of up to 65 HRC, high corrosion resistance, excellent thermal conductivity and is free from nickel and cobalt - ideal for cutting tools.

Are 3D-printed knives just as sharp and durable as conventional knives?

Yes, thanks to the THOR44 material and precise manufacturing using the SLM process, the knives achieve a comparable or even higher hardness and wear resistance than many conventionally manufactured knives

Can I integrate my own design or logo into the knife?

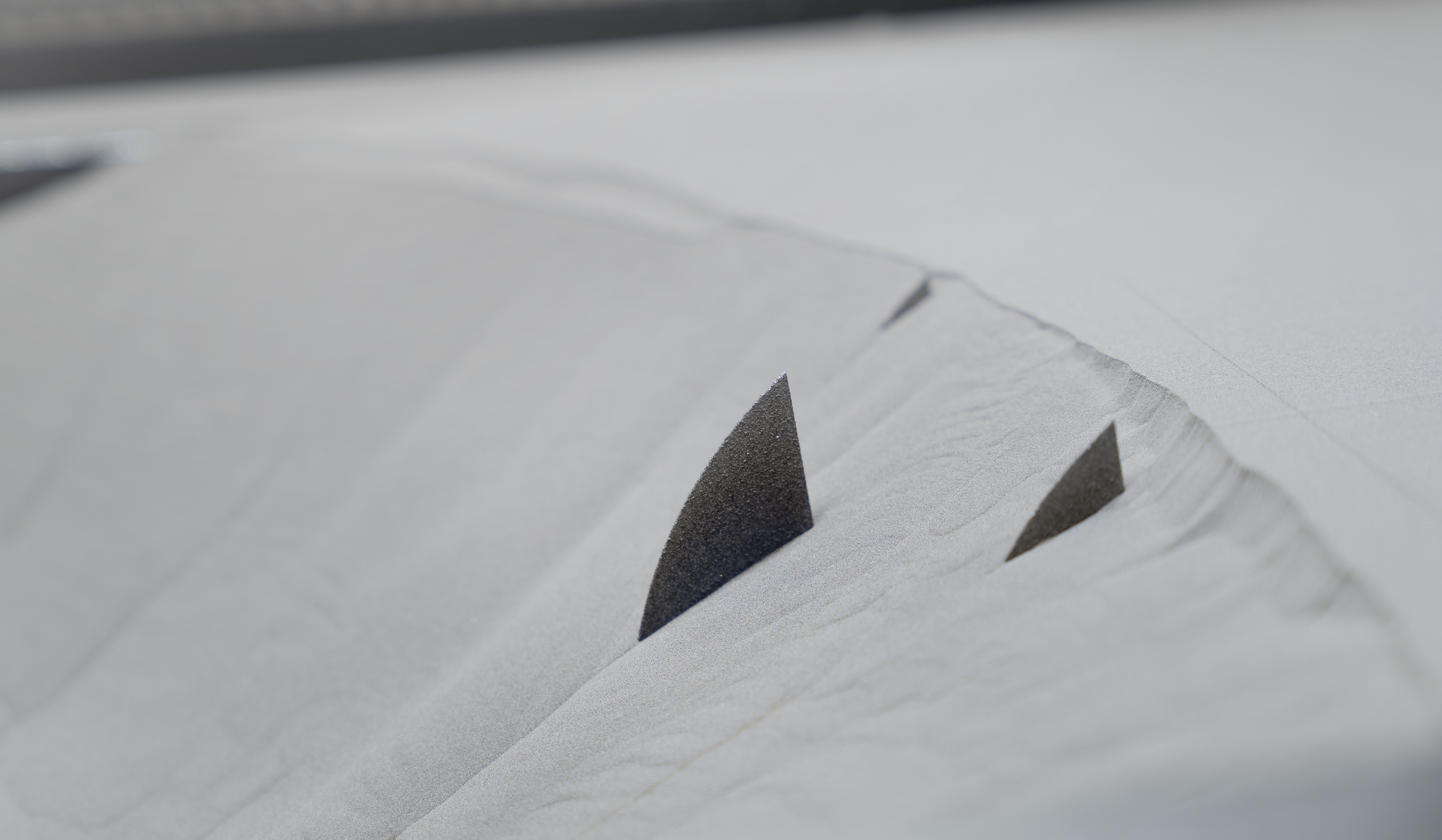

Yes, individual engravings, logos or lettering can be integrated directly into the blade or handle - without any additional processing steps. This makes every knife unique.

I don't have a 3D file - can PROTIQ help me?

Yes, PROTIQ offers support with data creation, design and technical implementation.

Deutsch

Deutsch English

English